Stabilisation and storage systems from Piller

Piller’s stabilisation and storage systems make it possible to optimise the various power sources in a microgrid, thereby reducing investment and operational costs.

Scroll To Explore

The aim is to efficiently and cost-effectively meet immediate and future microgrid requirements while reducing emissions to a minimum.

The Power of 10 approach to Microgrid power has been developed around modular hydrogen ready 10MW gas-fired gensets that can be paralleled from 30MW to 300MW and beyond.

This standardised component-based solution is deployable with all variable renewable energy resources (VRERs), stand-alone or in conjunction with the grid.

Now part of the Power Solutions Division of British engineering group Langley Holdings plc, our Microgrid offering meets immediate and future power requirements with a modular solution that is scalable, rapidly deployable and cost-effective.

Seamless integration of primary power and electricity generation combined with Integrated Power Conditioning & Switching (IPCS) technology, provides total or partial grid independence, either stand-alone or in conjunction with renewables.

Piller’s stabilisation and storage systems make it possible to optimise the various power sources in a microgrid, thereby reducing investment and operational costs.

Our flexible and cost effective engines compliment wind and / or solar renewable energy sources perfectly. They are capable of fast and frequent stop-starts and manage dynamic load response for grid balancing effortlessly.

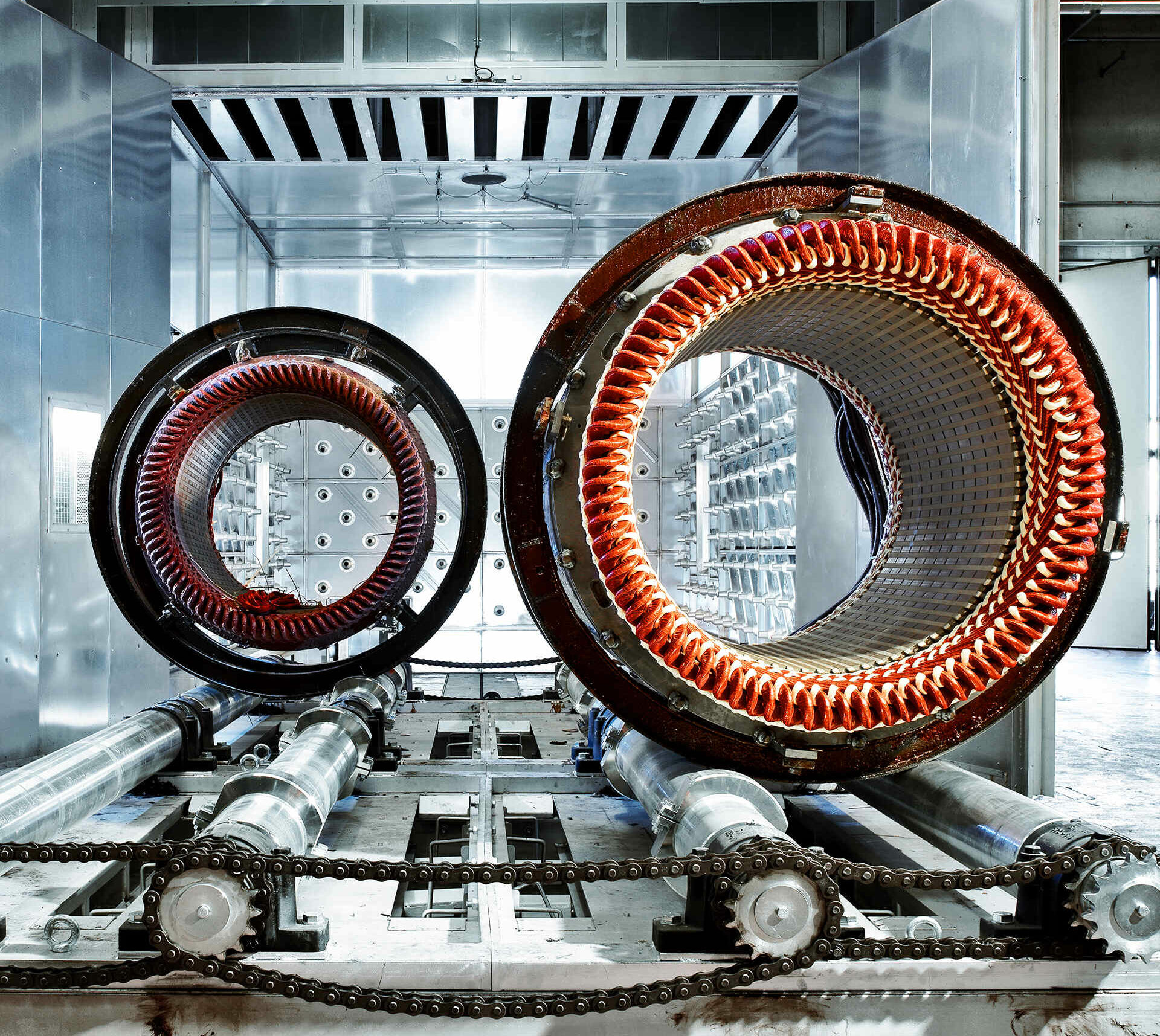

Marelli Motori alternators can start up fast and maintain high efficiency levels at part-load operation, always keeping emissions and fuel consumption low.

Bergen Engines is a leading manufacturer of medium speed liquid and gas-fueled engines and gensets. With high availability and efficiency levels, combined with excellent capability to meet quick and frequent load changes, Bergen’s engines combine perfectly with intermittent renewable energy resources that need balancing power. For Microgrid applications, Bergen’s largest single genset unit provides 11,830 kWe of power. These 10MW+ machines can easily be paralleled in modular ‘grow as you need’ deployments to more than 100MW for large industrial clusters and campus Microgrids for any application in any environment no matter how hostile. This makes them suitable for every type of Microgrid dedicated deployment, whether islanded or grid integrated.

Piller is a world-leading producer of power conditioning equipment and uninterruptible power supply (UPS) systems to mission-critical power applications.

Under the Power Solutions Division banner Piller solutions for Microgrids provide vital frequency and voltage stabilisation and grid gate technology that protects against outages in Microgrids whether integrated or in island mode.

It comprises 4 x Piller 2.5MW UB-V Series UPS modules electrically coupled to the power module via a single 10MW choke. Conditioned power is then distributed as required up to 10MW per IPCT module. Piller’s focus on frequency and voltage delivers fast response Microgrid stabilisation whatever the nature of the primary energy source, e.g. integrated with existing main grids, directly linked to local RERs, or on site generation.

Marelli Motori supplies fast response for different load situations with high efficiency according with the varied global grid codes and in perfect technical coordination with the Bergen Engine and Piller’s UPS system. The main target is to make the system work closing the power gap caused by black out or system failures of the local grid before the production line shut down or before running software will be interrupted.

The generator fast start-up main actor is the AVR: Marelli Motori’s D-Vo regulator, which gives better time fine tuning with a dual source power supply, which means that the AVR is always working to start immediately if needed.

Marelli Motori reacts on all possible load requirements with their high-efficiency machines. For the 10MVA generator developed for the Power of 10 solution the efficiency level is 98% at full load.

The Company is constantly working to improve its offer and is developing ventilation optimisation through reduced fan dimensions without compromising air flow (CFD analysis) and reduces constant iron losses using special lamination sheets with low specific losses.

Also the variable losses are taken into consideration by using slot filling copper versus insulation and with a high-performance insulation system.

Marelli Motori has been well known in the market for over 100 years, doing customised products according to specifications or national grid code.